The Anodized Aluminium Sheet is one of the most preferable materials to work as the architectural facade, interior, or part of the machinery. This metal has received an electrochemical process and thus is more resistant to corrosion, harder on the surface, and a beautiful gloss that can last more than decades. Slowly, others in the business of construction, automotive, signs and home design business are purchasing Anodised Aluminium Sheet due to its good looks and functionality.

It has a sleek, metallic look that makes it good for modern interiors and ornamental panels. In addition, its anodized layer protects it from UV radiation, severe weather, and contaminants, making it great for use both indoors and outdoors. Engineers and designers make sure their projects will last by using Anodized Aluminium Sheet, which doesn’t take away from the project’s beauty.

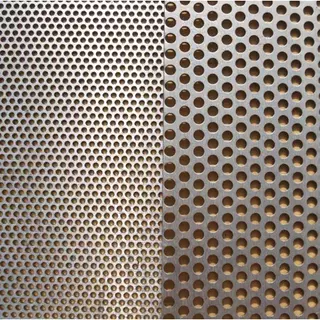

GI Perforated Sheets for Precise Engineering

GI Perforated Sheet is a durable and customizable option for structural efficiency, ventilation systems, or filtration parts. Galvanized iron (GI) is coated to keep metal from rusting, and the holes in it let air circulate freely, absorb sound, and lower the weight. HVAC, acoustic engineering, and agricultural are just a few of the fields that like to acquire GI Perforated Sheet since it is strong, flexible, and easy to build with.

The holes in it let it do more than just be a sheet of paper. It may be used as safety guards in machines, artificial ceilings, and fencing. A well-made GI Perforated Sheet has well-spaced holes and a strong zinc coating that sticks well, making it a product that works well under pressure and in the open air.

Flexible Use in Many Fields and Design Applications

More and more people want to buy Anodized Aluminium Sheet in industries that need high-end finishes that don’t need a lot of care. Anodized surfaces don’t show fingerprints, scratches, or fading, which is great for places with a lot of foot traffic. They may be used on everything from sleek kitchen cabinets to futuristic architectural cladding.

On the other side, GI Perforated Sheet is used for soundproofing, storage, and screening in factories. The punched-hole design helps with drainage, airflow, and filtration, which makes it a must-have for drainage covers, speaker grilles, and silo aeration floors.

These two materials do distinct things, but they work well together. The anodized aluminum sheet looks great and is resistant to corrosion, while the GI Perforated Sheet is useful because of its physical design and galvanized strength.

Building materials that are strong but light

Weight is an important factor to think about when choosing materials. Everyone knows that aluminium is strong but light. Anodized Aluminium Sheet keeps this benefit, which makes it easier to move and install while keeping its structural integrity. For projects where weight and handling are important, such as suspended ceilings or composite panels, architects choose to buy Anodized Aluminium Sheet.

Meanwhile, the GI Perforated Sheet has holes in it that make it a strong structure while using less material. This makes assemblies lighter overall and lets air or light pass through easily, which improves energy efficiency and system optimization.

Conclusion

Choosing the correct material is really important, whether you’re building a modern architectural masterpiece or making high-performance industrial equipment. Anodized Aluminium Sheet is the right mix of beauty and strength, and GI Perforated Sheet is useful, strong, and functional for a wide range of technical applications. Dinco.ae presents a carefully chosen variety of high-quality metal products for professionals in the UAE. Every sheet you buy helps to drive innovation.

Frequently Asked Questions (FAQs)

1. What are the primary benefits of using anodized aluminium sheets?

Anodized aluminium sheets are known for their corrosion resistance, increased durability, and elegant finish. They are lightweight, environmentally friendly, and ideal for decorative as well as structural uses.

2. Where can GI perforated sheets be applied effectively?

GI perforated sheets are perfect for ventilation systems, noise control in acoustic panels, drainage solutions, and decorative elements in architecture due to their strength and airflow capabilities.

3. How long do anodized aluminium sheets last in outdoor conditions?

Thanks to their enhanced surface protection, anodized aluminium sheets can last for decades in outdoor environments without fading, chipping, or corroding.

4. Can GI perforated sheets be customized based on design needs?

Yes, GI perforated sheets come in various patterns and sizes and can be customized to suit different design and functional requirements.

5. Is there a difference in sustainability between these two metal sheets?

Yes. Aluminium is 100% recyclable, and its anodized form minimizes maintenance needs. GI sheets are also recyclable but primarily valued for their protective zinc coating and structural efficiency.